The equipment is equipped with a built-in filtration module inside, which collects and filters the harmful waste gas at the evaporation source. The clean air after filtration is directly discharged into the room.

The mobile suction workbench series products have passed the ISO9001 Quality Management System certification, ISO14001 Environmental Management System certification, OHSAS18001 occupational health and safety Management system certification, EU CE and other relevant certifications. The application industries cover many fields such as education and scientific research, inspection and quarantine, medical and health care, food and pharmaceuticals, chemical engineering, environmental safety, national defense and military industry, etc.

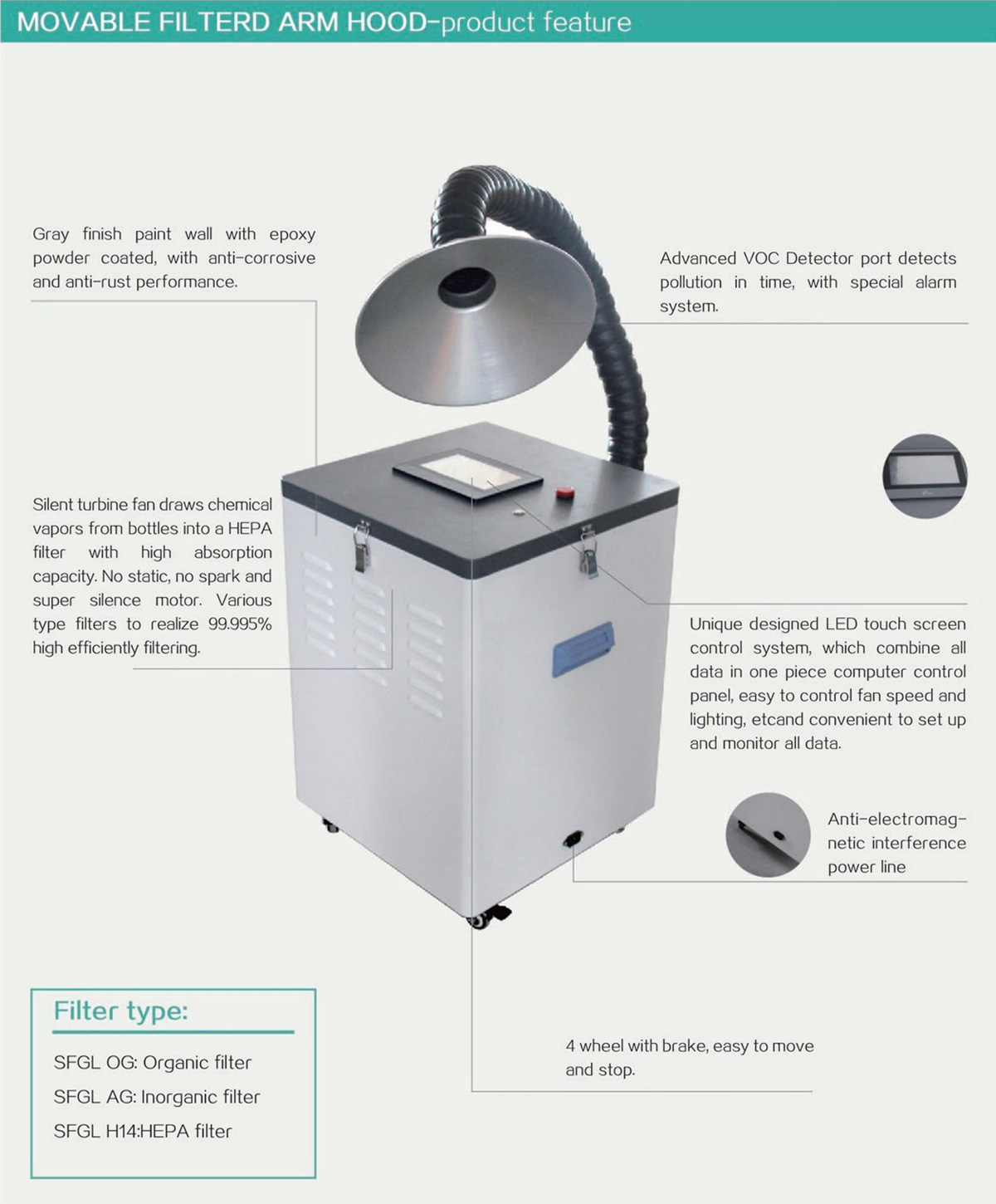

◆ Metal components: The main material is ≥ 1.2mm high-quality cold-rolled steel plate, electrostatically powder-coated, and covered with a lead-free lead-free coating that is resistant to corrosion and moisture to minimize the influence of corrosion and moisture.

The countertop adopts high-quality epoxy resin countertop, which does not deform and is firm and reliable. Optional physical and chemical board or ceramic countertop is available.

The cabinet is equipped with mobile drawers. The handles are of high-quality internal buckle type, which can store relevant experimental supplies.

◆ High-efficiency filtration system, arranged and distributed according to particle size, in accordance with ASTM standards, effectively targets acidic gases and organic gases, with strong adsorption capacity. For particle filters, high efficiency is adopted

HEPA filters have a filtration efficiency of 99.995% for particles larger than 0.3um.

◆ High-quality fans are adopted, with a current of 24 volts. The performance is stable, ultra-quiet, and there is no spark static electricity.

◆ Optional models of the filter: Optional organic filters (for the adsorption of organic solvents), ammonia filters (for the operation of ammonia reagents, organic reagents), inorganic filters (capable of adsorbing both organic solvents and inorganic acids), HEPA filters (with strong adsorption capacity for solid powders), and formaldehyde filters (for the operation of formaldehyde reagents) Organic reagents, nano photocatalysts, ultraviolet sterilization;

◆ Interface: Anti-electromagnetic interference power cord.

Working principle:

The equipment is equipped with a built-in filtration module inside, which collects and filters the harmful waste gas at the evaporation source. The clean air after filtration is directly discharged into the room.

| Product Model : | BR460MA / BR800MT / BR-MO1D |

| External dimensions: H850×W800×D620 | Voltage/Frequency: 220 V/50HZ |

| Noise: ≤60 dBA | Display screen: 7-inch LCD control screen |

| Filter: 2 Type B filters, power: 140W | External arm: Live joint arm - from cover to air inlet |

| Air processing capacity: 100 m³/h | Operating ambient temperature: -30℃ to 70℃ |

Tell us about your needs and we will get back to you as soon as possible.

+86 17315521755

Tailored systems for diverse scenarios: Bio-pharmacy labs, university research centers, chemical manufacturing plants.

Whatsapp:

+86 13961787792E-mail:

lab.safety@qq.comAddress:

No.29, Jingxin Road, Xibei Town, Xishan District, Wuxi CityCopyright © 2025 BringHS Intelligent Technology Co.,Ltd All Rights Reserved. Design by BONTOP.