Product Model: BR900Y-1

Specification Size: H1800*W900*D510mm

Internal Size: H1530*W796*D395mm

Background analysis

With the rapid development of social economy, the chemical industry has become a pillar industry of the national economy, and China has become a major country in the production and use of hazardous chemicals, in quantity and scale.

In recent years, with the occurrence of particularly major accidents, systematic safety risks have formed in the production, storage, transportation, use, disposal and other links of hazardous chemicals, seriously damaging the safety of people's lives and property, affecting high-quality economic development and social stability, and people talk about "chemical" color change. The policy environment, social environment and public opinion environment have encountered more severe challenges than ever before, and the safety work of hazardous chemicals needs to be comprehensively strengthened!

From the analysis of policies and regulations issued in recent years, the relevant regulatory documents for the storage of hazardous chemicals will be gradually updated and improved in the future, and since the issuance of Order 591 of the Regulations on the Safety Management of Hazardous Chemicals in 2011, including the newly released GB18265-2019, there are units for the storage of hazardous chemicals. Safety facilities and equipment such as monitoring, monitoring, ventilation, sun protection, temperature control, fire prevention, fire extinguishing, explosion prevention, pressure relief, gas protection, neutralization, moisture protection, lightning protection, static electricity prevention, corrosion prevention, leakage prevention, protective embankment or isolation operation shall be set up in workplaces according to the types and dangerous characteristics of hazardous chemicals produced and stored. And in accordance with national standards, industry standards or relevant state regulations to carry out regular maintenance of safety facilities and equipment, to ensure the normal use of safety facilities and equipment. The Ministry of Public Security has made clear provisions on the storage, management and use of controlled hazardous chemicals, which must have special facilities, and hazardous chemicals must be partitioned, classified and stored in separate warehouses. Strengthen the safety management of hazardous chemicals, prevent and reduce hazardous chemical accidents, ensure the safety of people's lives and property, and protect the environment.

Product function

BringHS reagent Cabinet (outer steel inner PP) series with compliance, environment, health and safety as the product concept, the design structure uses outer steel inner PP material, the middle with fireproof cotton; The storage of dangerous chemicals should be equipped with anti-theft, fire prevention, anti-static, ventilation, anti-corrosion, anti-leakage, double-lock management, monitoring, temperature control, explosion-proof, moisture-proof and other preventive safety measures to meet the storage requirements of dangerous chemicals; Set up obvious safety warning signs; And set up communication, alarm device, and ensure that in the applicable state.

The products have passed ISO9001 quality management system certification, ISO14001 environmental management system certification, OHSAS18001 occupational health and safety management system certification, EU CE and other related certifications. The application industry involves education and research, inspection and quarantine, medical health, food and pharmaceutical, chemical industry, environmental safety, national defense and many other fields.

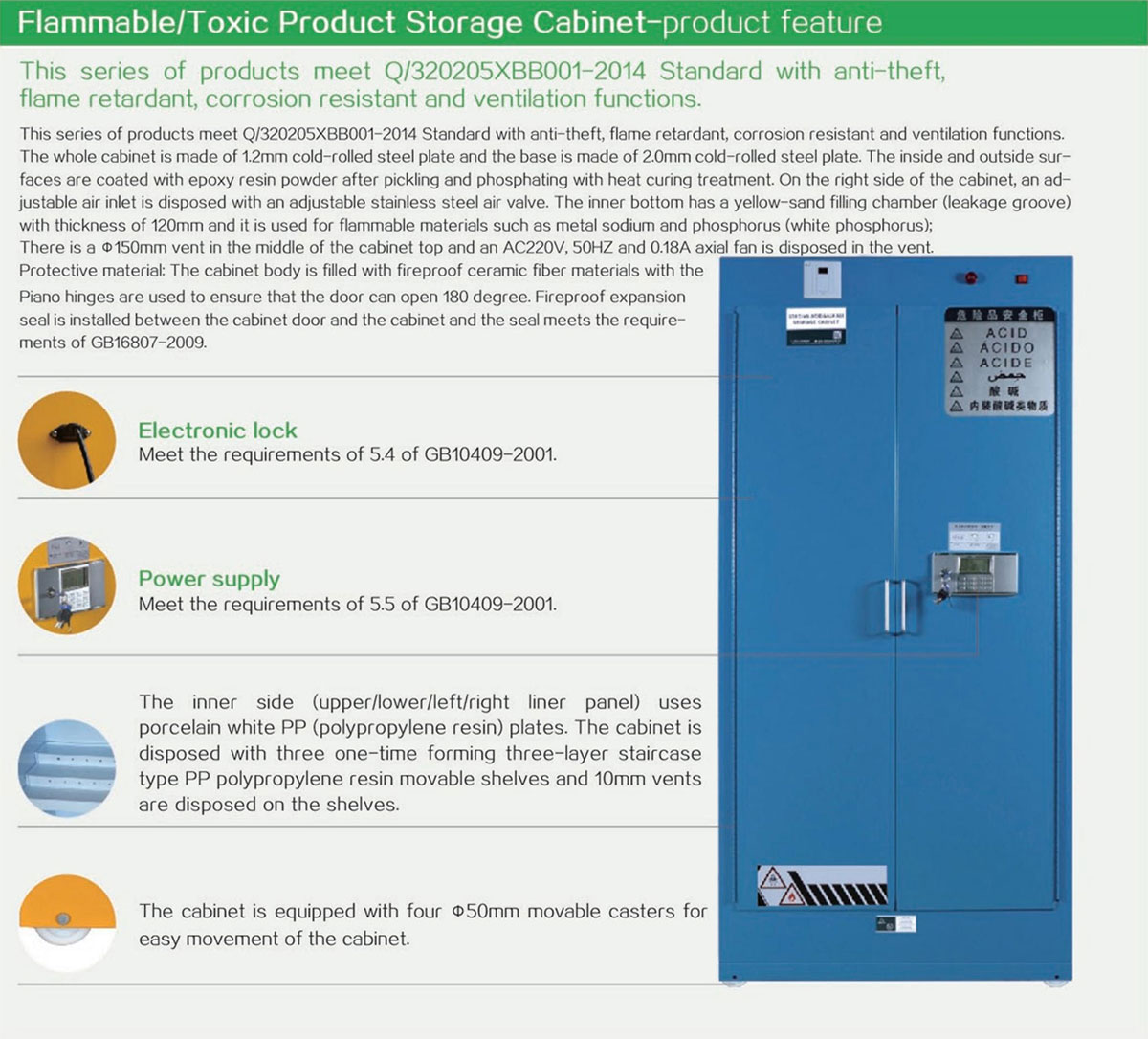

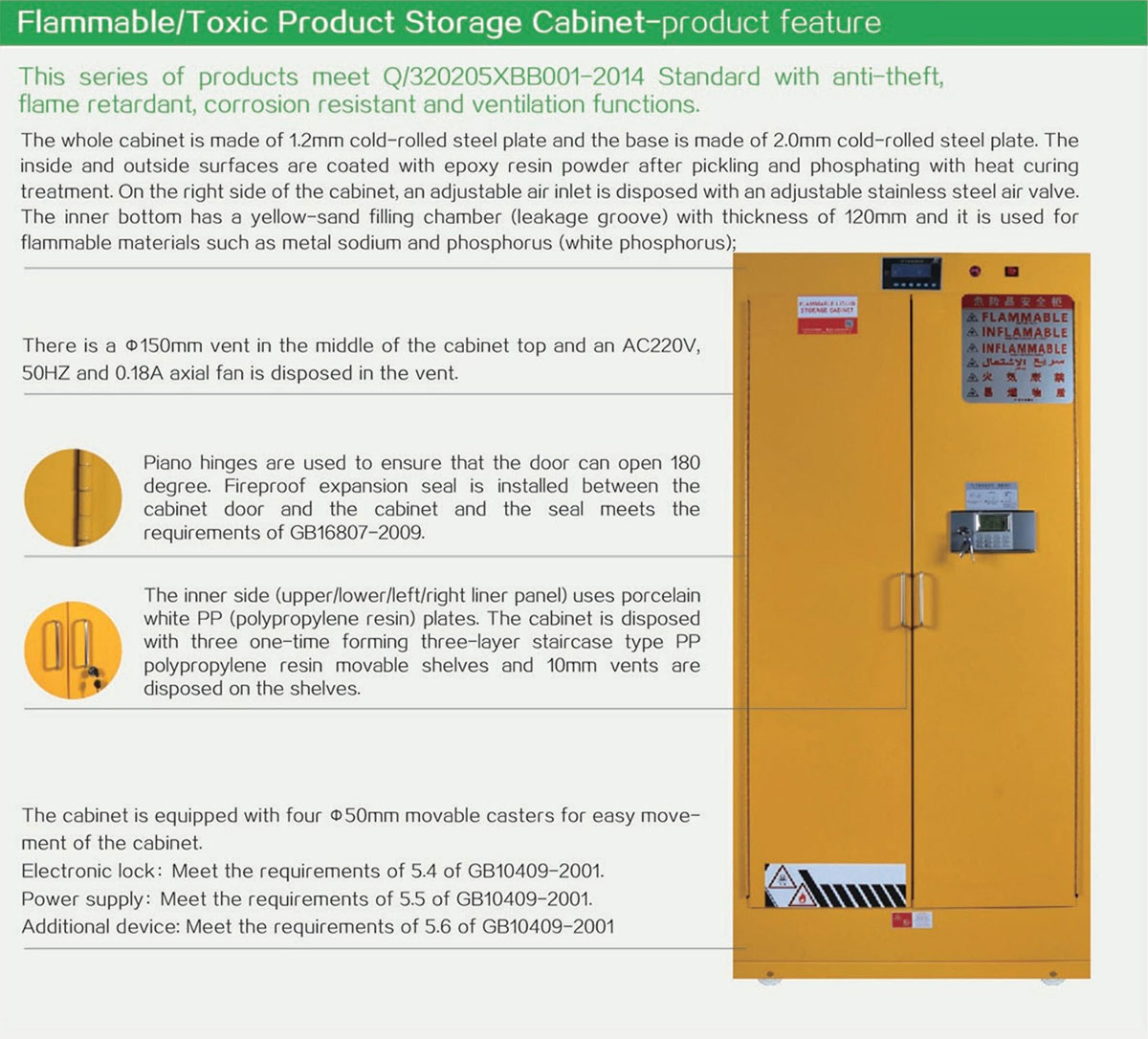

Product characteristic description

1. The cabinet is all made of ≥1.0mm cold-rolled steel plate, reinforced base, and the inner and outer surfaces are sprayed by pickling phosphating epoxy resin powder and heated curing treatment.

2.Cabinet inner liner (upper, lower, left, right lining board) are all made of porcelain white pp (polypropylene resin) board; The right side of the cabinet is provided with an adjustable air intake, a one-time forming PP adjustable air valve; The bottom layer of the cabinet is reserved for storing no less than 120mm thick yellow sand landfill cavity (leakage tank), which is used for burying flammable materials such as metal sodium and yellow phosphorus (white phosphorus). The baffle should be connected with the cabinet; The bottom of the cabinet is equipped with four φ64mm polypropylene moving casters to facilitate the movement of the cabinet; It is equipped with adjusting screw to facilitate the positioning and horizontal adjustment of flammable storage cabinet.

3. The cabinet is provided with three three-layer stepped PP polypropylene movable shelf, the layer plate is provided with 10mm air holes.

4. There is a φ150mm air outlet in the middle of the top of the cabinet, and an AC220V, 50H, 0.24A axial flow fan is built in the air outlet, the maximum air volume is 400m3/h, the speed is 1600 RPM /min, and the control switch is set at the top right corner of the cabinet; When the fan opens, push the air inlet in the middle under the cabinet door to open the state.

5. Fireproof material: The cabinet is filled with fireproof material ceramic fiber with thermal insulation effect;

6, Hinge: piano hinge, to ensure that the door can open 180 degrees. Install fireproof expansion seals between the cabinet door and the cabinet body, and the seals shall meet the requirements of GB16807/2009. (Environmental protection thermal expansion seals should be installed between the cabinet door and the cabinet body. When the temperature is 180 ° C, the sealing strip is partially expanded, and when the temperature reaches 750 ° C, the sealing strip is fully expanded, and the expansion ratio is 1:15 to ensure storage safety.

7. Electronic lock: should meet GB10409/2001 5.4 requirements.

8. Power supply: should meet GB10409/2001 5.5 requirements.

9. Additional device: should meet GB10409/2001 5.6 requirements.

10, Through the risk control device:

10.1 The air intake and adjustable air valve are arranged at the bottom of the cabinet. The adjustable air valve is flexible and can control the air volume.

10.2 The cabinet should be equipped with air vents, and the maximum wind speed of the air vents should be no less than 0.5m/s.

10.3 Equipped with a microcomputer time control switch, can automatically open and close the fan according to the time set by the user, the power switch indicator indicates whether the fan is working normally, can be automatically or manually controlled.

10.4 The diameter of the ventilation pipe should be φ160mm, and the ventilation pipe should be resistant to high temperature, flame retardant, corrosion, and meet the requirements of JGJ141.

11, Special security requirements: mechanical lock key, electronic code lock password should be kept by two people, two people should be present at the same time when opening.

12, Time control + temperature and humidity control integrated alarm device (optional)

The temperature and humidity controller should be configured on the top of the cabinet to monitor the relative temperature and humidity in the cabinet in real time, and display the set and measured values digitally. If the temperature and humidity in the cabinet exceeds the set measured values, the alarm will prompt immediately and the fan can be automatically turned on and off according to the time set by the user. The power switch indicator indicates whether the fan works normally and can be controlled automatically or manually. Power supply AC220V± 10% 50HZ, temperature control -40 ~ 80℃ (user set), humidity control 0 ~ 100% RH(user set)

13, VOC, temperature and humidity alarm detection alarm device (optional)

13.1 Intelligent control system: seven-inch LCD touch screen control system, real-time temperature and humidity environment monitoring, fan monitoring, VOC concentration environment monitoring system and integrated alarm system.

13.2 Temperature and humidity digital display setting and measurement value, high-precision sensor, when the temperature and humidity in the cabinet exceeds the set measurement value instant alarm prompt.

13.3 High quality centrifugal fan, 24 volt current, maximum air volume 570m3/h, speed 3100 RPM /min, stable performance, ultra-quiet, no spark static electricity.

13.4 High efficiency filtration system, according to particle size selection and distribution, in accordance with ASTM standards, effective against acid gas and organic gas, strong adsorption capacity, for particle filter, the use of high efficiency HEPA filter, for particles greater than 0.3um, filtration efficiency of 99.995%. Can effectively deal with formaldehyde, nitrogen dioxide, hydrogen sulfide, ammonia, chlorine, TVOCs and other irritating, odor and corrosive toxic and harmful gaseous pollutants. Filter options: organic filter (for organic solvent adsorption); Ammonia filters (operation of ammonia reagents, organic reagents); Inorganic filter (for organic solvents and inorganic acids, can adsorb); HEPA filter (for solid powder adsorption, strong capacity); Formaldehyde filters (for operation of formaldehyde reagents, organic reagents).

13.5 Iot system functions, mobile phone real-time query monitoring and other functions.

Product use and maintenance

1. Before use, the storage cabinet of inflammable and toxic products should be levelled and fixed. The bottom of the cabinet has four casters that can be moved to a fixed position.

2. Please connect the vent of the storage cabinet to the ventilation pipe.

3. Install 220V power sockets 2 meters above the wall behind the storage cabinet.

4. Users need to lay their own yellow sand at the bottom of the cabinet about 120mm in order to bury flammable and explosive reagents.

5. When the password lock is delivered, the initial value of the personal password is "1234" and the initial value of the management password is "123456". Replace the battery of the electronic code lock regularly. If it fails, please open it according to the code lock manual.

6. Mainly concentrated in the laboratory, for daily use, select special storage equipment;

7. The equipment location should not be placed in direct sunlight, water, heat sources or high voltage equipment near;

8. It is prohibited to place in areas with dense personnel and large flow;

9. Should be close to the ventilation facilities, the ground should be smooth, placed against the wall;

10. Must follow the important principle of classification management, according to the chemical properties of reagents to select the corresponding storage equipment;

11. Dangerous chemicals with chemical properties or fire prevention and fire extinguishing methods that contradict each other should be stored separately and independently;

12. In principle, the special storage device is only suitable for the storage of a single attribute of chemicals in the same cabinet, if you need to mix, please ensure that there is no chemical reaction between the stored chemicals;

13. The hazardous chemicals in the cabinet can not be stored for a long time, only suitable for temporary storage, according to the amount of reagents needed for relevant tests, ready-to-use.

Instructions for storing and storing hazardous chemicals

1. The chemicals in the storage cabinet cannot be stored for a long time.

2, The storage cabinet should be dedicated to the counter, shall not store non-hazardous chemicals.

3, The storage container should be intact, if there is damage should take immediate measures, such as transferring the container or timely use up.

4. Volatile corrosive gases should be tightly sealed and placed on the upper layer of the cabinet for discharge.

5, According to the oxidant, reducing agent, strong acid, strong base and other chemical properties of stratified compartments storage.

6, Metal sodium, yellow phosphorus (white phosphorus) and other flammable materials should be stored with the lowest layer of the cabinet inside the landfill cavity of not less than 120mm thick yellow sand.

7. Dangerous chemicals with chemical properties or fire prevention and fire extinguishing methods that conflict with each other should be stored separately and independently.

8. When storing controlled drug reagents in the storage cabinet, it can be implemented according to relevant regulations: double storage, double sending and receiving, double use, double double lock, such as the actual record of access and real-name registration.

9. For the hazardous chemicals that have been stored for too long and must be scrapped, and the waste liquid of the liquid tray at the bottom of the cabinet, special personnel should be responsible for timely cleaning and fixed-point destruction according to the waste of hazardous chemicals, and can not be directly poured into the sewer and ordinary garbage cans.

| Name: | Flammable and toxic chemicals storage cabinets(time control switch device) |

| Model: | BR900Y-1 / BR900Y-2 / BR900Y-3 / BR700Y / BR600Y-1 |

| Opening mode: | Double-door, manual |

| Lock: | Electronic password lock, dual-lock configuration |

| Shelves: | 3 one-piece PP stepped adjustable shelves |

| Specification Size: | H1800*W900*D510mm |

| Internal Size: | H1530*W796*D395mm |

| Net weight: | 120kg |

| Color: | Yellow/blue (epoxy coating) |

| Power supply: | AC220V/50HZ |

| Power: | 100W |

Tell us about your needs and we will get back to you as soon as possible.

+86 17315521755

Flammable and toxic chemicals storage cabinets (7 inch touch screen control)

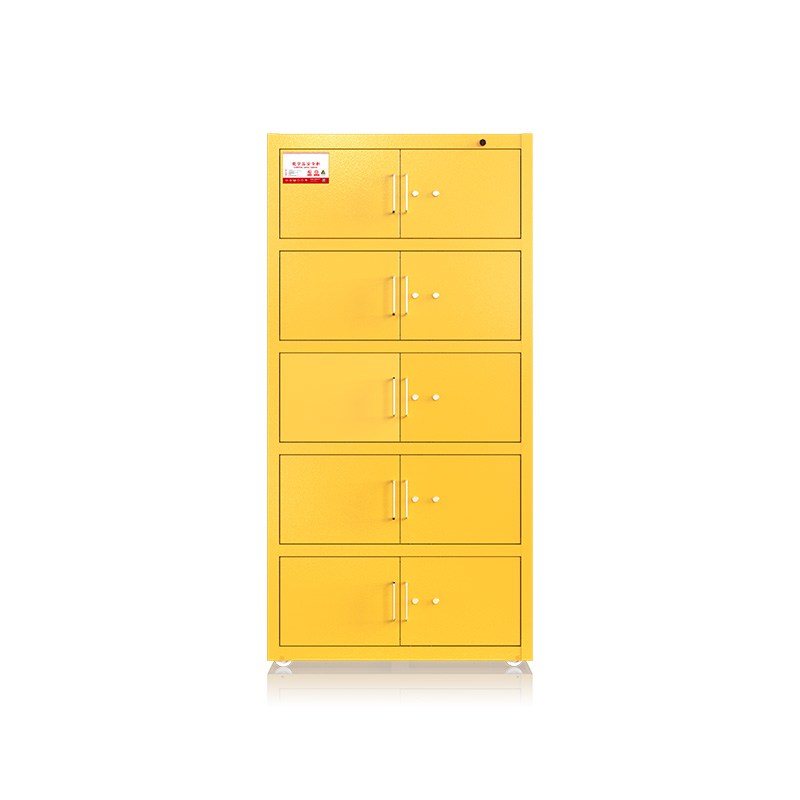

Flammable and toxic chemicals storage cabinets (five-tier Ten-door Drug Cabinet)

Flammable and toxic chemicals storage cabinets (time and space + temperature and humidity monitoring)

Flammable and toxic chemicals storage cabinets (time control switch device)

Flammable and toxic chemicals storage cabinets (time control switch device)

Tailored systems for diverse scenarios: Bio-pharmacy labs, university research centers, chemical manufacturing plants.

Whatsapp:

+86 13961787792E-mail:

lab.safety@qq.comAddress:

No.29, Jingxin Road, Xibei Town, Xishan District, Wuxi CityCopyright © 2025 BringHS Intelligent Technology Co.,Ltd All Rights Reserved. Design by BONTOP.