The primary filter is used for the primary filtration of air purification. It has a simple structure and is made of non-woven fabric, metal wire mesh or glass fiber. Its appearance is flat or folded. The filtration efficiency for dust particles larger than 5μm is 20%-80%. The structural integrity needs to be tested.

The medium-efficiency filter serves as a bridge between the upper and lower parts. It is made of glass fiber or polypropylene, and is available in bag or plate type. It can filter particles of 1-5μm with an efficiency of 60% to 90%.

Background Overview

In the current era of rapid technological development, numerous industries such as education and research, inspection and quarantine, food and pharmaceuticals, biomedicine, chemical engineering, semiconductors, and new energy are booming. They are constantly exploring the unknown, seeking breakthroughs, and conducting a large number of complex and challenging experimental research and application production. While these activities are promoting the progress of the industry, they also hide many risks. For instance, the frequent use of hazardous substances tests the professional quality and safety protection ability of the operators. The handling of the testing, storage and disposal stages is of vital importance. Some experiments and production have strict environmental requirements. The specific environment is related to the smooth progress of research and production, the accuracy of results, operational safety and personnel health. Environmental construction and protection cannot be ignored.

The company's products are centered on safety and environmental purification, designed to meet the specific needs of various fields. They cover safe storage of hazardous substances, intelligent storage of chemical reagents, safe ventilation for preventing leakage and gas diffusion in chemical experiments, safe ventilation for operations in sterile biological environments, air purification and environmental protection, and high-cleanliness environmental purification, etc. Our full range of products covers all aspects including safe storage, operation protection, environmental purification, and waste collection. We are committed to addressing the safety and reliability issues in specific production or testing environments, providing a strong guarantee for the safe development of the industry and safeguarding scientific research and production activities.

Scene problem

Inhalation risks of air pollutants: This includes harmful gases produced by experiments, industrial dust, chemical waste gases, etc. Long-term or high-concentration inhalation can lead to respiratory diseases, poisoning, and even cancer.

Risk of exposure to bioaerosols: Bioaerosols may be generated during laboratory operations and biological processing, posing an infection risk to laboratory personnel. In severe cases, it can cause an epidemic.

Chemical substance contact hazard: Chemical substances widely present in experiments and production processes, such as solvents, heavy metals, corrosive substances, etc., may enter the human body through skin contact, inhalation or accidental ingestion, causing acute or chronic poisoning.

Extreme temperature and humidity conditions: Unsuitable temperature and humidity conditions may affect the comfort and health of workers. Long-term exposure to extreme environments can cause heatstroke, frostbite, respiratory diseases, etc.

Cross-contamination of air quality: Cross-contamination of air between different regions, such as contamination between different experimental areas within a laboratory or different production processes within a factory, may lead to distorted experimental results or a decline in product quality.

Microbial cross-contamination: In scenarios where strict control of the microbial environment is required, cross-contamination may lead to experimental failure, product contamination or personnel infection...

Professional fields such as laboratory research and development, industrial production and manufacturing, biosafety and environmental control, and cleanroom technology and application all require strict environmental control and purification measures to ensure the accuracy, safety and efficiency of experiments and production.

Solution

The comprehensive air purification system, through efficient filtration, intelligent control and ventilation, comprehensively improves and maintains the air quality in the experimental and production environment, providing health protection for the staff.

The special dust control plan focuses on source control and efficient dust removal. By integrating industrial dust collectors and other equipment, it thoroughly resolves the issue of dust pollution in industrial production and ensures a clean production environment.

Biosafety protection measures cover the use of biosafety cabinets and air disinfection and purification, creating a safe and sterile working environment and effectively preventing the leakage of bioaerosols and microbial contamination.

The comprehensive environmental control plan focuses on the precise implementation of temperature and humidity control, creating a comfortable and safe working environment to ensure the efficient operation of scientific research and production. At the same time, it is equipped with appropriate air conditioning, humidification and dehumidification equipment to achieve precise environmental control.

Filter

Series Overview

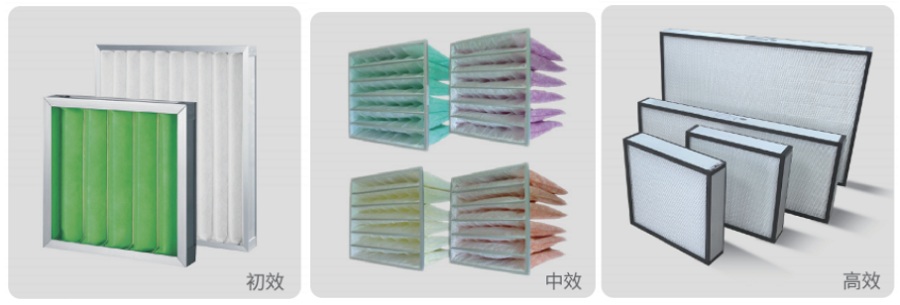

The filter product series are diverse, including primary, medium and high-efficiency filters. The primary filter is made of non-woven fabric and other materials. It has a simple structure and can filter particles larger than 5 microns with an efficiency of 20% to 80%. It is used for primary filtration to prevent clogging. Medium-efficiency filters use glass fiber and other materials, with a precision of 1-5 microns and an efficiency of 60%-90%, intercepting medium particles and reducing the load on high-efficiency filters. It efficiently adopts ultra-fine glass fiber filter paper, achieving a filtration efficiency of 99.97% - 99.995% for particles with a diameter of 0.3 microns, removing tiny particles and is suitable for high-cleanliness environments.

Series of applications

As a core component of purification equipment, filters play a crucial role in various fields of equipment. Its high-efficiency filtration performance ensures the cleanliness of air quality and the working environment, providing an indispensable guarantee for high-demand industries such as electronic semiconductors, pharmaceuticals, food processing, and aerospace. Through fine filtration technology, it effectively intercepts and removes particles, bacteria, viruses and other harmful substances in the air, preventing these pollutants from causing damage to sensitive equipment and products, thereby extending the service life of the equipment and improving product quality.

Product characteristics

The primary filter is used for the primary filtration of air purification. It has a simple structure and is made of non-woven fabric, metal wire mesh or glass fiber. Its appearance is flat or folded. The filtration efficiency for dust particles larger than 5μm is 20%-80%. The structural integrity needs to be tested.

The medium-efficiency filter serves as a bridge between the upper and lower parts. It is made of glass fiber or polypropylene, and is available in bag or plate type. It can filter particles of 1-5μm with an efficiency of 60% to 90%.

High-efficiency filters are the key to high cleanliness. Their core is ultra-fine glass fiber filter paper, with a box structure. They have a filtration efficiency of 99.99% to 99.995% for 0.3μm particles.

Tell us about your needs and we will get back to you as soon as possible.

+86 17315521755

Tailored systems for diverse scenarios: Bio-pharmacy labs, university research centers, chemical manufacturing plants.

Whatsapp:

+86 13961787792E-mail:

lab.safety@qq.comAddress:

No.29, Jingxin Road, Xibei Town, Xishan District, Wuxi CityCopyright © 2025 BringHS Intelligent Technology Co.,Ltd All Rights Reserved. Design by BONTOP.